Swiss family business

A Swiss family-owned business since 1874

We employ around 130 people in our five profit centres. Our company has been located in Netstal for more than 140 years and is firmly anchored in the region. As an attractive employer, we promote the economic region of Glarus.

Today we present ourselves as a modern plastics processing company. With a product from A. & J. Stöckli you are investing in proven and future-proof Swiss quality.

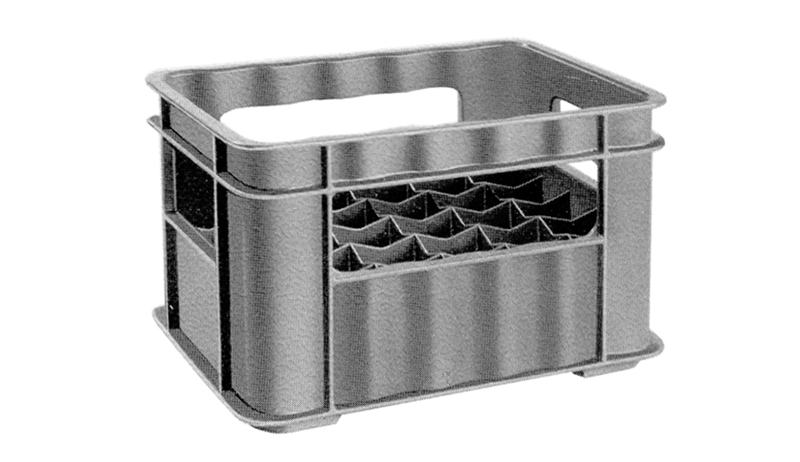

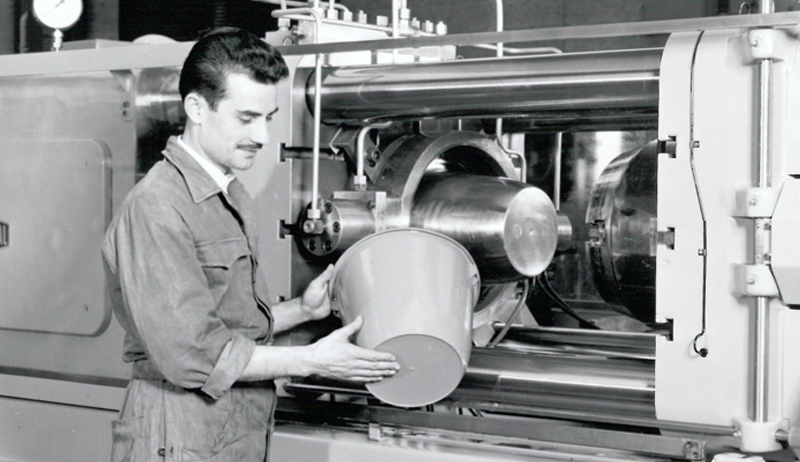

Plastic injection moulding

In the last decades, we focused on and specialized in the area of various injection moulding and specialized methods. Apart from the conventional injection moulding we also offer in-mould-decoration (IMD), variotherm technology, gas-injection-technology (GIT), cascade injection moulding as well as the overmoulding of inserts. A. & J. Stöckli AG stands for plastic production made in Switzerland.

Quality

In cooperation with our business partners, we define the specific quality specifications and check the products accordingly. We regularly carry out material, product and production inspections and record the results, thus ensuring that the individual customer requirements for the plastic parts are consistently implemented. We are ISO 9001 and 14001 certified.

Environment

Whenever possible, we rely on recycling. By recycling up to 1000 tonnes of various plastics per year, we can avoid massive emissions of greenhouse gases. For electrical energy, we can rely on our in-house hydroelectric power station and the hydroelectric energy generated in the area. The cooling systems of the machines and tools as well as the heating of the buildings are operated with CO2-neutral energy from the groundwater. The waste heat from the production facilities is in turn used to heat the premises. A. & J. Stöckli no longer makes use of fossil energy. Thanks to these technologies, the company is at the fore of the conservation of resources and environmental friendliness.

Social commitment

As a regionally and internationally active company, we take responsibility. We support regional and national foundations and educational institutions, promote the education and training of our employees and see a good working environment as a pillar of our success.