Innovative layout design for control panels

The appearance of electrical appliances is currently changing. Slowly but surely, mechanical buttons and switches are disappearing from the user interfaces. These are replaced with touchscreens or simple touch buttons, also in combination with contactless gesture control, which are suitable for semi-transparent or non-transparent surfaces.

With increasing digitalization, the requirements with regard to functional integration are also increasing, especially in the field of electronics. The panel is increasingly becoming a human machine interface (HMI). We are now offering the merging of control, design and functional surfaces.

Touch fields are still combined with mechanical controls. Washing machines in particular continue to have rotary knobs, as users are very used to this interface. On and off switches on electric stoves are still standard, as they give a feeling of security. A trend towards removing all buttons and switches can nevertheless be seen.

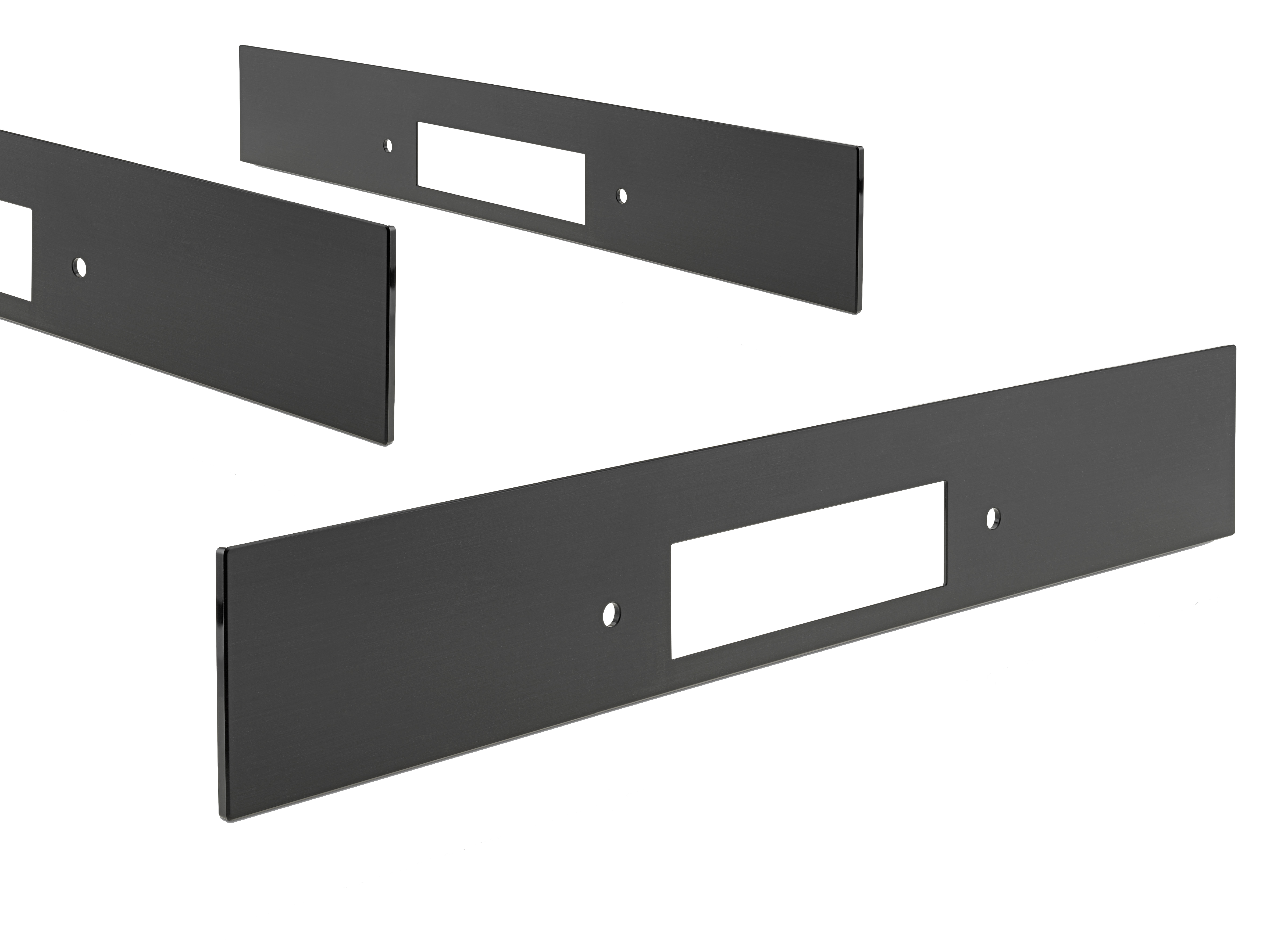

More and more premium devices are being offered with innovative design and operating concepts, for example the dead-front effect. When the device is switched off, the user sees a uniform front, for example in brushed metal, and a control panel is only visible when the backlight is activated. New sensor technologies meet these trends efficiently and with a high degree of design freedom.

New design options for control panels

The appearance of electrical appliances is currently changing. Slowly but surely, mechanical buttons and switches are disappearing from the user interfaces. These are replaced with touchscreens or simple touch buttons, also in combination with contactless gesture control, which are suitable for semi-transparent or non-transparent surfaces.

With increasing digitalization, the requirements with regard to functional integration are also increasing, especially in the field of electronics. The panel is increasingly becoming a human machine interface (HMI). We are now offering the merging of control, design and functional surfaces.

Touch fields are still combined with mechanical controls. Washing machines in particular continue to have rotary knobs, as users are very used to this interface. On and off switches on electric stoves are still standard, as they give a feeling of security. A trend towards removing all buttons and switches can nevertheless be seen.

More and more premium devices are being offered with innovative design and operating concepts, for example the dead-front effect. When the device is switched off, the user sees a uniform front, for example in brushed metal, and a control panel is only visible when the backlight is activated. New sensor technologies meet these trends efficiently and with a high degree of design freedom.

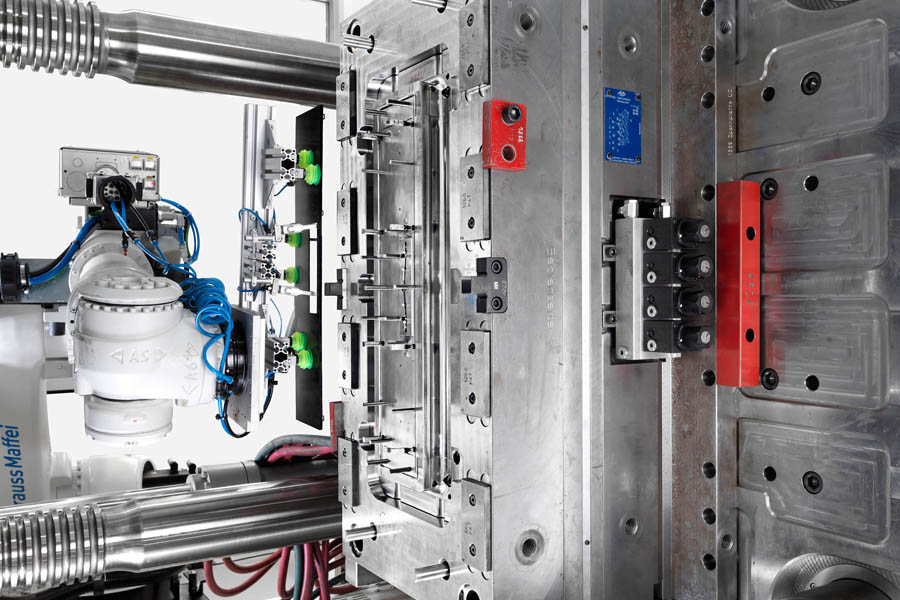

Combination of IMD and IML process

The panel is decorated using what is known as IMD technology (In-Mold Decoration). A multi-layer paint package in a customer-specific design is transferred to the plastic component during the injection molding process. At the same time, a sensor film, i.e. a film printed with conductor tracks, is inserted into the tool (IML: In-Mold Labeling). The plastic is then injected between the two films, which means that a functionalized component can be produced in just one process step.

Surface coating requirements

The design of the front panel for devices is changing rapidly. The trend is towards control panels with an elegant touch or gesture control surface, which are integrated directly into the touch display as the first step in the off-screen area. We can provide suitable decoration and sensor technologies for the reliable implementation of these constructions and functional features. A number of the first successful series applications have shown that these innovative layouts are not only technically but also economically feasible.

Possible applications

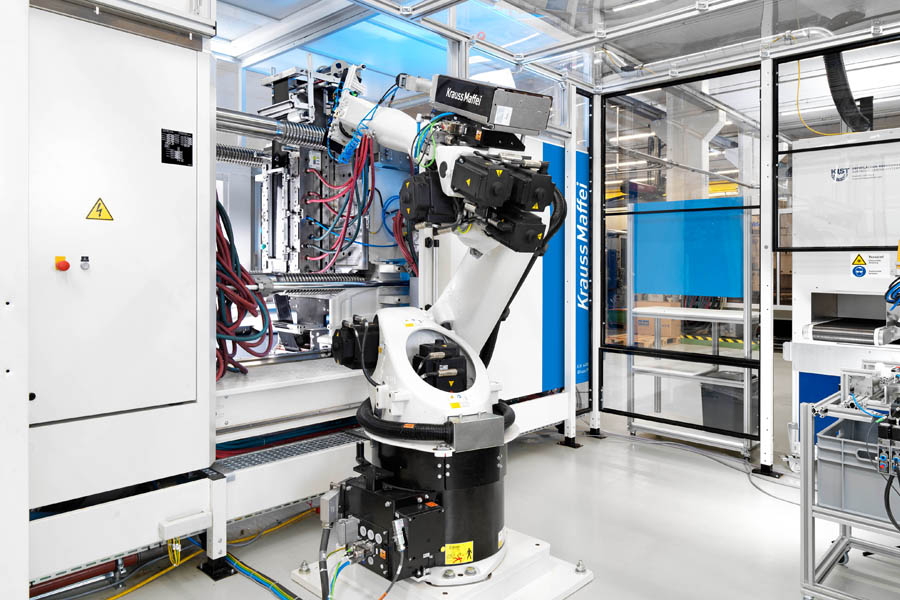

Optimized process sequence

We use the handling during the in-mold decoration process to insert the sensor film. The result is an economical, highly automated process that is suitable for a large number of different applications:

- Large covers with touch controls

- Different product lines (price ranges) can be produced with the same tool

- Touch functions can be programmed anywhere on the entire sensor film and the additional functions can be hidden in lower price ranges

- Uninterrupted design creation

- Replacement for currently used expensive touch displays

- Curved components

- Human machine interface in general

New design options for buttons

Washing machines, refrigerators and electric stoves with touch panels have been on the market for several years. Traditionally, conductive connections between the control panel and the electronic circuit board were made using springs. The innovative sensor technology completely eliminates all bulky mechanical components. Recently, sensor foils have been used in washing machines from well-known manufacturers. The sensor technology ready for series production offers a high degree of design freedom not only for reasons of space. Thanks to the use of capacitive sensors, practically every position on the display can be made functional. This opens up a multitude of design options in the display area, as the touch buttons can be positioned anywhere. Recently, this advantage has made it possible, for example, to position all switches and buttons directly on the touch display. This allows any controls that are currently in the off-screen area to be placed in the actual display area.

This freedom of design extends not only to the buttons, but also to the geometry of the plastic front panels. These new sensor foils consist of high-resolution, conductive metal structures (metal grids) on a PET substrate. These thin functional films are mechanically robust and elastic. This means that they can be integrated not only into flat but also into curved plastic components, which distinguishes them from the predominantly ITO-coated sensor foils used. ITO is a brittle material that cannot withstand this type of deformation and therefore cannot be integrated into curved components.

Thanks to the use of highly conductive silver metal grid structures, these new sensors have several advantages over ITO. Their electrical conductivity is up to ten times higher. This ensures reliable contact detection, even through several millimeter thick plastic front panels (cover glasses). An additional, time-consuming calibration of the touch system from the touch controller to the touch sensor is also not necessary when using metal grid sensors.

Contactless gesture control

Cost-efficient production despite sophisticated design

New sensor designs are produced in large quantities in an efficient roll-to-roll process. This cost advantage opens up possibilities for designing a sophisticated display. The ability to efficiently integrate the sensor further lowers costs. The sensor film is integrated on the back of the plastic front panel in a fast industrial process. So far, sensor foils have been connected using a lamination process. We are now able to integrate these sensor foils directly into the plastic part using IML (In-Mold Labeling).

Decoration technologies using the hot stamping process

Flexible capacitive sensors offer considerable design freedom with regard to the arrangement of the control panel and the geometry of the control panel.

In contrast to the conventional method, the electrical connection is now integrated directly during the printing process and only needs to be connected to the control, after which the sensor is immediately functional.

Sustainable technology

Convince yourself of the economic advantages of the IMD process from A. & J. Stöckli AG. Control panels of ovens are usually painted or made of real material, e.g. B. aluminum executed. Or the desired surface look is only created during subsequent processing. Production steps such as painting or electroplating are mostly carried out in low-wage countries. They are a cost factor and at the same time ensure a negative environmental balance. IMD enables injection molding and decoration in one step and is also ideally suited for recycled plastic materials.